Tinuvin® 1600

High-performance UV absorber

for highly demanding outdoor applications

Plastic additives for

high-performance thermoplastics

Tinuvin® 1600– An Outstanding Technology

Tinuvin® 1600 represents a major milestone in UV absorber technology.

- Provides extremely long-lasting UV protection for high-performance thermoplastics

- Very low surface roughness

- Exhibits outstanding UV absorption capacity, resulting in minimal

loss of optical properties for stringent weathering requirements - Very low volatility allowing for outstanding processing characteristics

- Sets new industry benchmark in ultra high durability, not achievable

with current UV technologies

Tinuvin® 1600 has been specifically developed for the long-lasting protection of thin-layer applications for exterior uses, allowing plastic sheets, films and fibers to retain their transparency and mechanical properties enabling also very low surface roughness for extended periods of time. Tinuvin® 1600 belongs to the HPT [Hydroxyphenyltriazine] chemistry class, exhibiting very low volatility, excellent thermal stability and good substrate compatibility in a variety of polymeric resins, allowing very easy processing and improving productivity. It imparts far superior durability that traditional UV absorbers of the benzophenone, benzotriazole (BZT) or cyanoacrylate classes cannot achieve.

Tinuvin® 1600 is the solution for the most demanding thin-section applications in terms of exposure to UV light providing superior lifetime enabling less maintenance, improving waste management and replacement of other materials like mineral glass.

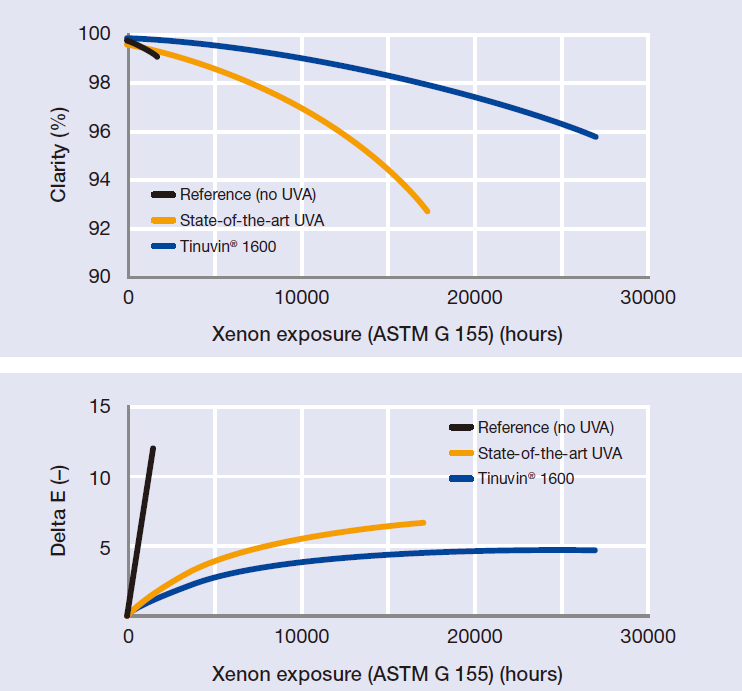

A polycarbonate caplayer, was tested according to ASTM G 155 (Xenon Exposure) until embrittlement. Tinuvin® 1600 provides outstanding performance compared to the best-in-class at significantly lower concentration levels. For example, optical properties such as clarity and color (represented by delta E) are well maintained.

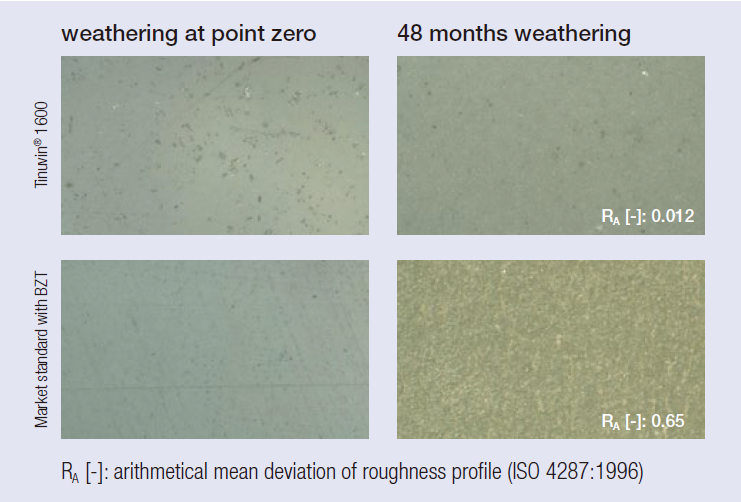

Atlas EMMAQUA Outdoor accelerated weathering with surface roughness RA [-] measurement

Opal multi-wall PC sheets were tested according to Atlas EMMAQUA outdoor accelerated weathering in Arizona for 4 years. Tinuvin® 1600 enables lower surface roughness leading to excellent clarity retention, improved dust build up resistance and extended auto cleanability by rain.

Recommended Applications

Tinuvin® 1600 helps to extend the life expectancy of outdoor products under strong exposure to UV light, including:

- Monolithic and multi-wall PC sheets for ultra high durability architectural and automotive glazing applications

- Oriented PET films for photovoltaics, window films, displays, protective films and other long-term applications

- PMMA films/laminations for very durable specialty applications like window profiles, photovoltaics and demanding construction applications

- PET and PA fibers

- SAN, ASA high-performance plastics applications, e.g. in building and construction and automotive applications

- Other extruded or blown thin-film applications requiring extended UV protection

Asia

BASF East Asia

Regional Headquarters Limited

Plastic Additives

45th Floor, Jardine House

No. 1 Connaught Place

Hong Kong

Phone: +852 2731-0111

Middle East

BASF Plastic Additives

Middle East S.P.C., Bahrain

International Investment

Park (BIIP)

Road 1518, Al Hidd,

Kingdom of Bahrain

Phone: +973 17 585-232

+973 17 585-235

South America

BASF S.A.

Plastic Additives

Sede Administrativa

Av. das Nações Unidas

14.171, Morumbi

04794-000 São Paulo, SP

Brasil

Phone: +55 11 2039-2797

Europa

BASF Lampertheim GmbH

Plastic Additives

Chemie Strasse 22

68623 Lampertheim

Germany

Phone: +49 621 60-0

North America

BASF Corporation

Plastic Additives

100 Park Avenue

Florham Park, NJ 07932

USA

Phone: +1 973 245-6000

Note

The descriptions, designs, data and information contained herein are presented in good faith, and are based on BASF’s current knowledge and experience. They are provided for guidance only, and do not constitute the agreed contractual quality of the product or a part of BASF’s terms and conditions of sale. Because many factors may affect processing or application/use of the product, BASF recommends that the reader carry out its own investigations and tests to determine the suitability of a product for its particular purpose prior to use. It is the responsibility of the recipient of product to ensure that any proprietary rights and existing laws and legislation are observed. No warranties of any kind, either expressed or implied, including, but not limited to, warranties of merchantability or fitness for a particular purpose, are made regarding products described or designs, data or information set forth herein, or that the products, descriptions, designs, data or information may be used without infringing the intellectual property rights of others. Any descriptions, designs, data and information given in this publication may change without prior information. The descriptions, designs, data and information furnished by BASF hereunder are given gratis and BASF assumes no obligation or liability for the descriptions, designs, data or information given or results obtained, all such being given and accepted at the reader’s risk. (08/2016)

® = registered trademark of BASF SE

BASF SE

BASF SE