Thermal conductive filler is a filler that fills the resin to give heat dissipation (make it easier to conduct heat).

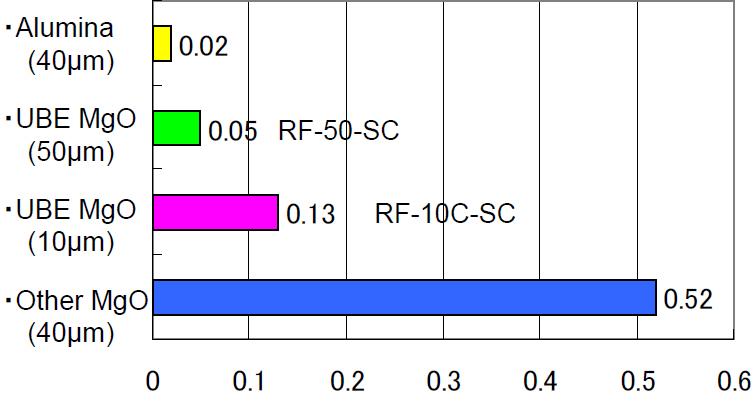

In the past, MgO was often shunned as highly hygroscopic.

Our MgO has improved hygroscopicity by firing at high temperature (1800-2000 ℃) and

unique reaction conditions.

We are a comprehensive manufacturer of MgO, and we can provide a stable supply

through integrated production from raw materials.

We offer high thermal conductivity filler MgO with excellent thermal conductivity at low cost.

| Product Name | Description |

|---|---|

|

Average Particle Size 70~110μm |

|

|

Average Particle Size 70-110μm, Vinyl-based Surface-Treated Products |

|

|

Average Particle Size: 40~70μm |

|

|

Average Particle Size 40-70μm, Vinyl-based Surface-Treated Products |

|

|

Average Particle Size: 40~70μm, Phenyl-Based Surface-Treated Products |

|

|

Average Particle Size: 40-70μm, Amino surface-treated products |

|

|

Average Particle Size 7~15μm |

|

|

Average Particle Size 7-15μm, Vinyl-based Surface-Treated Products |

|

|

Average Particle Size 7-15μm, Phenyl-Based Surface Treated Products |

|

|

Average Particle Size: 7-15μm, Amino surface treatment products |

|

|

Average Particle Size 4-10μm |

|

|

Average Particle Size 4-10μm, Vinyl-based Surface-Treated Products |

UBE Thermal Conductive MgO Filler

MgO as the Radiation Filler

Characteristic of UBE MgO filler

・Improved anti hydration properties by high temperature sintering (1,800-2,000゚C)

and original controlled reaction condition.

・Stable supply by integrated manufacturing.

・Lower price

Characteristice of substances

| Filler | Thermal conductivity(W/mk) | Specific resistance | Hardness | Water resistance |

| (W/mK) | (Ω cm) | |||

| Magnesia | 42~60 | 1×1017 | 6 | △ (UBE MgO filler○) |

| Alumina | 26~36 | 1×1015 | 12 | 〇 |

| Hexagoal boron nitride | 31~60 | 1×1014 | 2 | 〇 |

| Aluminum nitride | 180~270 | >1×1014 | 8 | △ |

※ These figures refer technical books published by Technology Information Institute co.ltd. in Japan and refer public information on web site.

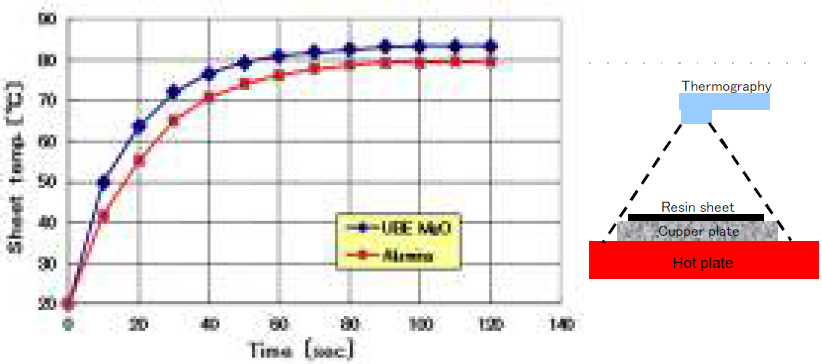

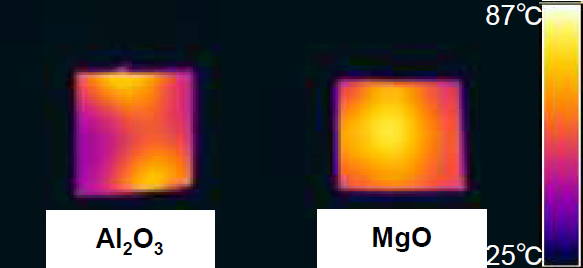

High thermal diffusivity

Thermal diffusion of compound resin, EEA-resin : filler = 1:3 (weight ratio.)

Application

●Thermoplastic resin:PA6, PPS, PBT

●Molding resin:EMC, LED

Ube Material Industries,Ltd.

Ube Material Industries,Ltd.